From the start, the Lean movement has focused on tools and methods that were unpacked from kaizen. Why? Because they are easier to sell. This was an enormous mistake – a major strategic error – that continues to this today. It’s time to refocus on kaizen.

From the start, the Lean movement has focused on tools and methods that were unpacked from kaizen. Why? Because they are easier to sell. This was an enormous mistake – a major strategic error – that continues to this today. It’s time to refocus on kaizen.

Lean tools and methods must be used within the context of kaizen. Why? Because kaizen is how you learn to think. Kaizen is how you learn TPS and lead the transformation. Kaizen is how you develop people. Kaizen is how you achieve significant business results quickly. The organizations that have had the most success with Lean are those who are committed to kaizen.

Your strategy is simple: Kaizen, which means to simultaneously improving all dimensions of the work. You must quickly move away from what you have been doing, called kairyo in Japanese, which is improvement in one dimension such as reducing the number of steps in a process. It only leads to failure.

Kaizen is the essential ingredient. It develops the mindset that establishes the pathway for success. Without it, you’ve got nothing more than the appearance of improvement. That’s why it is important to understand and correctly practice kaizen; Toyota-style, industrial engineering-based kaizen. That is the only way to obtain achieve material and information flow, and the associated low costs, high productivity, high quality, and short-lead times.

These blog posts will help you better understand kaizen and hopefully motivate you to want to practice kaizen.

- Leadership Development for Business Impact

- Mother Kaizen

- Lean Thinking vs. Kaizen Thinking

- Toyotya’s One Best Way

- Kaizen Evolution

- Kaizen: A Comprehensive Business Strategy

- The Humanity of Shingijutsu-Kaizen

- Shingijutsu-WOW

- Toyota-Style Kaizen

- The Power of Kaizen

- The Back Story – Shingijutsu-Kaizen

- Back to Basics

- New Book: Shingijutsu-Kaizen

- The Back Story – Kaizen Forever

- New Book: Kaizen Forever

- The Most Important Thing

- The 5-Day Kaizen

- Origin Of The Phrase “Kaizen Event”

- Toyota’s Secret

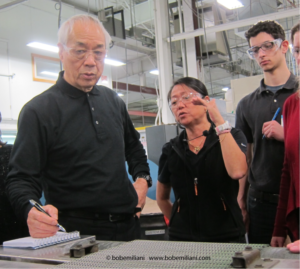

- Chihiro Nakao: An Amazing Teacher

- Ohno’s Problem-Solving Methods

- Focus On Flow

- Reflecting On Shingijutsu-Kaizen

- Nakao-san and Shingijutsu-Kaizen

- Shingijutsu-Kaizen Conference: Day 1

- Shingijutsu-Kaizen Conference: Day 2

- No Lean Without Kaizen

- Early TPS Training

Want more information? These books will be a big help to you:

Shingijutsu-Kaizen: The Art of Discovery and Learning and Kaizen Forever: Teachings of Chihiro Nakao contain lively and detailed descriptions of the kaizen mindset and method. Toyota Kaizen Methods: Six Steps to Improvement and Kaizen Express: Fundamentals for Your Lean Journey provide important complimentary but less lively descriptions of kaizen. Better Thinking, Better Results: Case Study and Analysis of an Enterprise-Wide Lean Transformation shows the financial and non-financial results that Toyota-style, industrial engineering-based kaizen can achieve. The Lean Turnaround: How Business Leaders Use Lean Principles to Create Value and Transform Their Company and Transforming Health Care: Virginia Mason Medical Center’s Pursuit of the Perfect Patient Experience explain why the foundation of Lean management is kaizen.

All successful Lean transformations had kaizen as their foundation. As Chihiro Nakao says: “Master the basics.” Kaizen.