Can Lean management – the learning management system, the thinking management system – exist in organizations that do not practice kaizen?

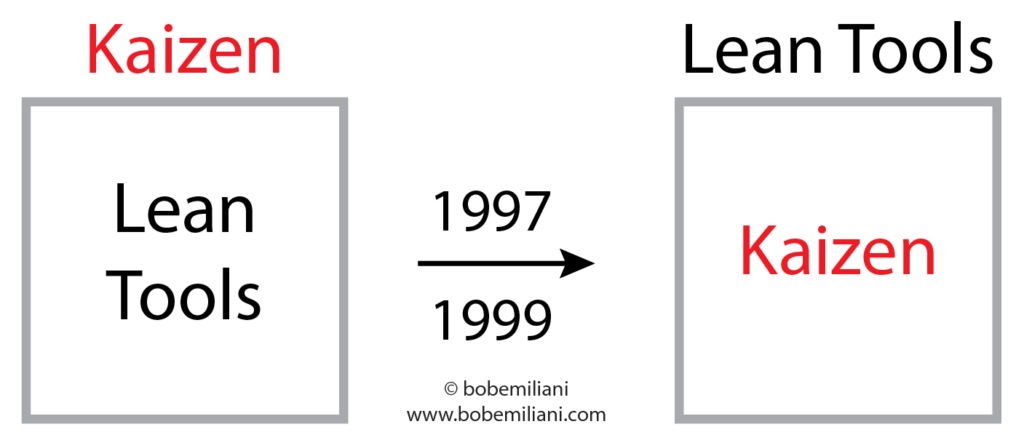

In the old days, kaizen made use of various tool and methods (so-called “Lean tools”) to achieve improvements. In recent years, more and more organizations use Lean tools separate from kaizen to make improvements. Something happened around 1997 to 1999 that led to this critical change in how kaizen is performed.

The image illustrates the change that has occurred. Kaizen is the process that utilizes “Lean tools” (left side, correct), while Lean tools are being used outside of the kaizen process (right side, incorrect). Using Lean tools outside of kaizen presents four problems:

- Improvements will be small compared to what they could be, resulting in a much slower Lean transformation.

- It turns kaizen into an infrequent “event.”

- People will not learn kaizen and therefore fail to develop and improve their personal and organizational capabilities.

- Big problems linger uncorrected.

Fundamentally, you don’t need Lean tools to tell you where or when to do kaizen. That’s not their purpose. Instead, you only need problems, of which there are many.

Recall that when former Toyota-trained engineers first started teaching Toyota’s production system in the U.S. in 1988, the focus was on the system and kaizen as the process for making improvements. The books, Kaizen Forever, Shingijutsu-Kaizen, and Toyota Kaizen Methods, by Isao Kato and Art Smalley, follow in that tradition and informs readers on how to correctly practice kaizen. This and other resources can help you return to the pre-1997 way of understanding and doing kaizen.