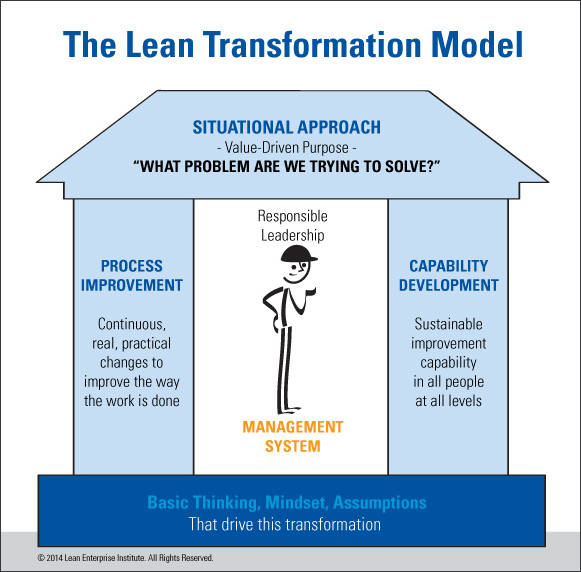

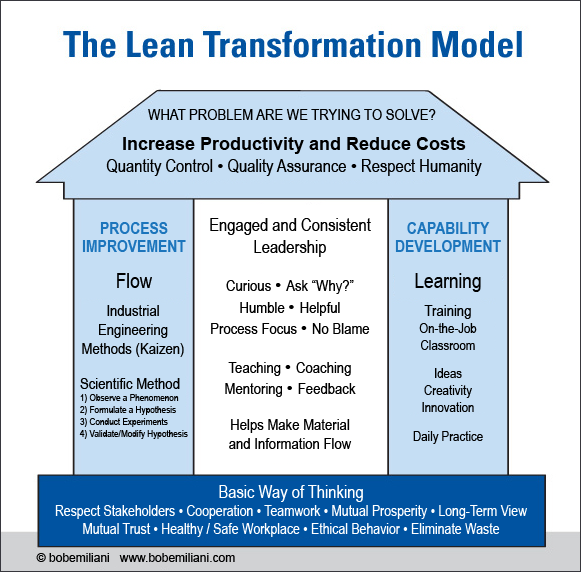

The Lean Enterprise Institute and the Lean Enterprise Academy have recently created a Lean transformation model whose focus is value. Based on my training in TPS/TW by Shingijutsu, the model is not quite right and lacks important information.

But, being a professor, and someone who likes to think and improve things, I thought it might help people to see the model – whose focus is waste – with a greater level of detail to make it more specific and actionable. The details that I have inserted are consistent with the history and evolution of Toyota, inclusive of management’s thinking and practice, as well as my experience with TPS and kaizen.

It is very important to recognize that the “Basic Way of Thinking” is the foundation for success. Too many business leaders lack this “Basic Way of Thinking,” and, as a result, are unable to emulate Toyota in even the most simplistic of ways. Their Lean efforts fall far short of expectations and usually do harm to people. Effective Lean transformations must begin with many big changes in the “Basic Way of Thinking” for entire senior leadership teams.