The headlines are alarming: “Lean Production: Inside the Real War on Public Education” and “Lean Production Comes to Public Education (Parents and Teachers Must Fight This Process).” Has Lean really come to public education? No, that has not actually happened, and it will never happen until people – education leaders, union leaders, teachers, and staff – comprehend and put into practice the “Respect for People” principle.

It ceases to be Lean the moment it is used for bad.

Lean must do no harm.

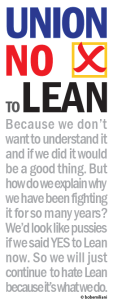

One of my great disappointments is how, for nearly 100 years, labor union leaders have preferred to use progressive (Lean) management as a wedge issue to create contention between labor and management, when instead they could work to understand Lean management and hold management accountable to its correct practice. That alone would be worth the price of union membership dues. And union members would be proud to know they are led by knowledgeable, honest, and capable leaders who truly have their members’ interests at heart (stable employment, wage increases, and better benefits and working conditions – what every working person wants, whether top leader or bottom worker).

One of my great disappointments is how, for nearly 100 years, labor union leaders have preferred to use progressive (Lean) management as a wedge issue to create contention between labor and management, when instead they could work to understand Lean management and hold management accountable to its correct practice. That alone would be worth the price of union membership dues. And union members would be proud to know they are led by knowledgeable, honest, and capable leaders who truly have their members’ interests at heart (stable employment, wage increases, and better benefits and working conditions – what every working person wants, whether top leader or bottom worker).

Labor unions, of which I am a member (AAUP since 2005), look stupid when their leaders fail to get all the facts and learn about things that are of importance to the union, its members, the organization, and its stakeholders. The characterization of Lean in public education, while correctly criticizing management’s bungled practice of Lean, fails to inform members of the distinction between Lean done right (mutual trust, mutual benefit, mutual prosperity) and Lean done wrong (zero-sum, win-lose). Articles portraying Lean as bad are written and re-published again and again to strengthen and expand its utility as a wedge issue and keep members united against the threat of Lean. Union leaders’ total failure to understand that Lean must do no harm is an enormous disservice to union members, as well as the managers they negotiate with.

I have been characterized as “the greatest advocate for workers and the ‘Respect for People’ principle” as a result of my 20-year effort raise awareness of the “Respect for People” principle and how to apply it in the strategic and day-to-day practice of leadership and management. Consistent with my work, I periodically contact union leaders to offer my help to improve their understanding of Lean and the critical importance of the “Respect for People” principle, which both labor and management persistently fail to understand. I recently contacted a union leader. Here is what I said to him in an e-mail (sent from my university e-mail account):

Hello Mr. Smith – I am a member of the AAUP union and a long-time practitioner of Lean management, first when I worked in industry and later as a university professor. I understand you are a critic of Lean, and I understand why. Most leaders of organizations misunderstand and misapply Lean principles and practices. As a result, they do harm to people. It is not Lean management when harm is done. They are doing something else, which they unfortunately also call “Lean.” I have experienced this first-hand (what I call “fake Lean”), but I have also experienced Lean done right (what I call REAL Lean).

I have always felt that union leadership should take the time to understand Lean management – REAL Lean, not fake Lean – because they could serve an important role to hold managers accountable to practicing REAL Lean, which would result in better outcomes for people, especially union membership.

I would like to begin a dialog with you on this topic, if you would be so kind.

Here is my bio https://bobemiliani.com/biography/ and resume https://bobemiliani.com/wp-content/uploads/2018/04/emiliani_webCV.pdf

And here’s a few blog posts and an article (last item) that I think you will find interesting:

https://bobemiliani.com/eliminating-the-six-criticisms-of-lean/

https://bobemiliani.com/winners-and-losers/

https://bobemiliani.com/golf-and-lean/

https://bobemiliani.com/why-is-lean-important/

https://bobemiliani.com/great-lean-leaders/

https://bobemiliani.com/goodies/respect_for_people.pdf

Finally, I am beholden to no one. I am a passionate, independent advocate of REAL Lean, and harsh critic, as you are, of fake Lean. I hope to speak with you soon. Thank you.

Sincerely,

Bob Emiliani, Ph.D.

Here is the reply I received from Mr. Smith 43 minutes after I sent the e-mail:

“Thanks.”

That reply, as I interpret it, is a quick brush-off. It illustrates to me a willful desire to remain ignorant, to manipulate members, to win elections, and to do harm to the image and reputation of labor unions and their members. There is no challenge in contention, and unions’ influence is severely diminished by ignorance.

Like the labor movement, the roots of Lean are in the progressive era – a time when activists sought to elevate workers, improve pay and working conditions, and improve relationships with management, in part by replacing zero-sum (win-lose) conventional management practice with non-zero-sum (win-win) progressive (Lean) management. Though they share a common heritage, generations of union leaders have incorrectly attributed Lean done wrong to Lean itself, when instead it was the managers in industry who misunderstood and Lean and who practiced it incorrectly. Unions can help correct that, but only if they understand the true meaning and intent of Lean management.

Lean management represents an area of common interest to both labor and management, and an opportunity to align themselves for their own benefits, as well as the benefit of all stakeholders. Will top labor leaders ever recognize that?

(Disclosure: Prior to being an AAUP member, I was a business unit manager for 4 years at a company with IAM-represented labor.)