What standard do you hold yourself to when someone asks you questions about Lean management or Toyota management? The standard could vary as widely for a person as it can from person-to-person. There are at least eight possible standards to choose from:

- Say “I don’t know”

- Guess at the answer

- Say what you heard

- Say what you read

- Say what you did

- Say whatever you wish to further your own interests

- Obfuscate, mislead, or even lie

- Carefully check facts to make sure you are as accurate as is humanly possible

If you are a professor, as I am, then you don’t have the range of choices that other people have – whether you are a promoter of Lean or a Lean practitioner. Professors have only one choice: answer questions factually, as best that they can. Professors hold themselves to a high standard as a result of the lengthy process they went through to obtain their terminal degree (i.e., lots of training in research, critical thinking, fact-finding, analysis, questioning, and criticism). Professors are also held to high standards by their peers through internal and external review of their work, and by students.

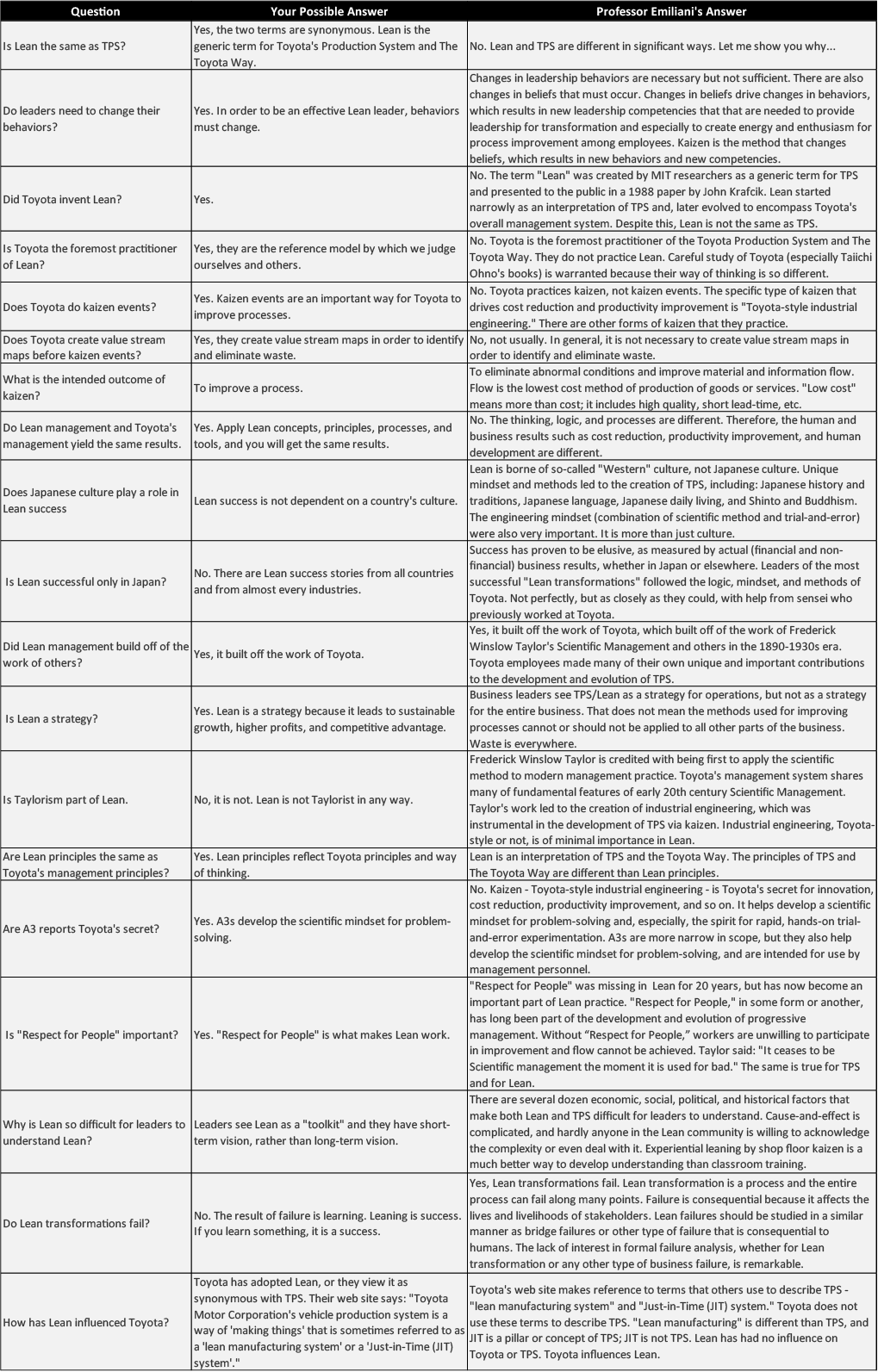

When I am asked questions about Lean, TPS, and so on, I answer them based on my own experience as a practitioner, observer, teacher, researcher, and writer. But not everyone can or is willing to answer questions that way. Below are some questions that I get from students in class, and two columns of answers. The “Your Possible Answer” column reflects common answers to the questions, while my answers are shown in the adjacent column.

The Table below is not meant to make a claim as to “who’s better.” Instead, it illustrates how different professional or personal standards yield different answers. It reflects higher levels of critical thinking and questioning that any subject matter deserves in order to improve people’s understanding and practice of it.